Welcome to the inaugural PI Circular – Healthcare Edition, your go-to source for the latest innovations, insights, and updates in healthcare packaging!

We are thrilled to launch PI Circular – Healthcare! We hope you find the content valuable, and as always, we welcome your feedback to help us enhance future editions. Each issue will kick off with our insights on a current topic related to healthcare packaging. You’ll also find updates on recent PI innovations, technical expertise in healthcare thermoforming, insights into healthcare sustainability, innovative customer stories, and summaries of upcoming industry events!

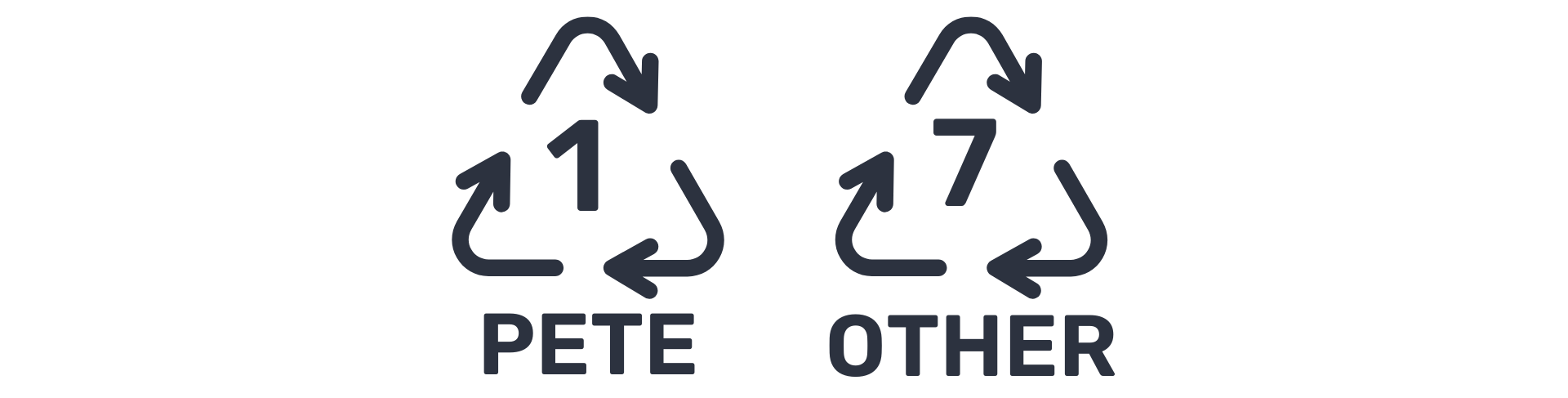

PETG: #1 or #7? The Truth About Resin ID Codes

In the realm of packaging materials, the correct identification and classification of resins is essential. One such resin, PETG, often raises questions regarding its classification. Because it’s much less susceptible to becoming brittle, PETG is suitable for higher temperature processes such as radio frequency (RF) sealing, heat sealing, sterilization, and other procedures required by sterile barrier packaging.

PETG is widely used within the healthcare packaging industry due to its superior properties, but which Resin Identification Code should PETG be classified as?

Historical Context of RICs

Resin Identification Codes (RICs) were introduced in the 1980s by the Society of the Plastics Industry to improve manual recycling sortation by providing a standardized way to identify different types of plastics. Although RICs can aid in the manual recycling process, the RIC symbol does not deem an article recyclable. Rather, RICs are used solely to identify the plastic resin used to manufacture the part. Therefore, any recycling guidance or environmental claims shall not be placed near the code.

Purpose of ASTM D7611-21

The Resin Identification Codes have undergone several updates to improve their effectiveness and accuracy. The latest revision, ASTM D7611-21, reflects updates in industry practices and definitions for each RIC. Resin Identification numbers and corresponding resins are listed below.

- 1 = PETE (polyethylene terephthalate)

- 2 = HDPE (high density polyethylene)

- 3 = V (vinyl)

- 4 = LDPE (low density polyethylene)

- 5 = PP (polypropylene)

- 6 = PS (polystyrene)

- 7 = OTHER (includes multilayer)

ASTM D7611-21 updates the RIC system by providing clearer guidelines on labeling and identification. These changes aim to enhance the recycling process and improve the efficiency of waste sorting. The update emphasizes the importance of accurate resin identification and its role in facilitating better recycling outcomes.

The current standard calls for an equilateral triangle, a Resin Identification Number, and an Abbreviated Term for polymeric material.

Figure 1: Correct Resin Identification Codes

Figure 2: Chasing Arrows, Incorrect Resin Identification Codes

Using symbols such as the chasing arrows for resin identification does not comply with the guidelines of ASTM D7611-21. Chasing arrows are universally associated with recyclability. Therefore, using chasing arrows for resin identification can be deceptive or misleading since not all resins within the identification system are widely recyclable today.

Differences Between PET, APET, and PETG

While PET, APET, and PETG are chemically related, their differences result in varying Resin Identification Codes

- PET – RIC #1: Due to its high-strength barrier, durability and versatility, polyethylene terephthalate (PET) is one of the most popular plastic choices for thermoforming. The resulting resistance to tampering and outside elements makes PET suitable for sensitive applications such as food containers, beverage bottles, and medical device packages. According to ASTM D7611-21, PET “must exhibit a melting peak temperature between 225°C and 255°C” and be produced from polyesters made from “terephthalic acid (or dimethyl terephthalate) and monoethylene glycol wherein the sum of terephthalic acid (or dimethyl terephthalate) and monoethylene glycol reacted constitutes at least 90 percent of the mass of monomer.”

- APET- RIC#1: Amorphous polyethylene terephthalate (APET) is a subgroup of the PET family. It contains the same polyester makeup as PET but refers to the specific stage at which the material is still amorphous before molding. APET is commonly used for high-volume, thin-gauge packaging, and is becoming a popular material for rigid sterile barrier packaging. Manufacturers must treat APET with care, as overheating it or heating it for too long can cause the plastic to become hazy or brittle. Since APET resins meet the requirements of monomer mass makeup and peak melting temperatures for PET, Resin Identification Code #1 is the correct classification.

- PETG – RIC #7: Polyethylene terephthalate glycol-modified (PETG) is created by adding the glycol modifier cyclohexanedimethanol (CHDM) to standard PET. The introduction of CHDM inhibits hazing and crystallization by adding a secondary diol monomer to the polymer structure and breaking up the linear ethylene glycol chain. However, since PETG has a peak melting temperature and chemical composition outside the bounds of the PET definition, the correct Resin Identification Code for PETG is #7.

Importance of Correct Identification

Extended Producer Responsibility (EPR) legislation and the EU Packaging & Packaging Waste Regulations (PPWR) are increasingly focusing on correct material identification. Inaccurate identification of plastic type could result in fines, penalties, and removal from market.

Although proper resin identification is incredibly important, we must remember that RICs do not represent recyclability. In order to prove true recyclability, especially for specialized medical grade PET and APET resins, it is best practice to adhere to guidelines set forth by the APR’s Recyclability Recognition Program.

Good Information Courses

Are you a packaging engineer, procurement professional, or a sustainability expert looking to learn more about the thermoforming process? PI has launched a free, in-depth online course covering everything from the polymers commonly used in thermoforming to the recycling process. This short yet comprehensive course is a great way for anyone to become well versed in thermoforming and rewards you with a certificate upon completion. Begin online today.

Stay tuned for our upcoming course focused entirely on healthcare packaging sustainability!

Our Sustainable Packaging Engineer, Sarah Webber, appeared in Medical Design & Outsourcing to provide key strategies for embracing the EU’s Packaging & Packaging Waste Regulation. Access the article here.

Beckman Coulter’s Path to Sustainability Success

We partnered with Beckman Coulter to design a robust, sustainable packaging solution for their sensitive diagnostic consumables. Through years of collaborative engineering, we achieved a final product that ensures protection, minimizes material use, and enhances recycling opportunities. As a result, we received a 2024 IoPP Ameristar Award for medical device packaging excellence!

Read more about their story here.

Our team is recharging for the summer in anticipation of many exceptional events this fall:

- Our Sustainable Packaging Engineer, Sarah Webber, will be on a panel discussing sustainable design strategies at the Sustainable Packaging Coalition’s Advance event in Chicago, IL from September 30th – October 2nd

- Our healthcare team will be exhibiting at the PDA Universe of Pre-Filled Syringes and Injection Devices Conference 2024 on October 22nd – 23rd

- Our healthcare team will be at Pack Expo in Chicago, IL from November 3rd