Understanding the Language of Sustainability As the push for sustainable packaging grows,…

Welcome back to PI Circular! In this edition, we will discuss the potential role of bio-based plastics in a circular economy. The White House announced a goal in March of this year to transition 90% of plastic production from fossil fuel-based feedstocks to bio-based alternatives over the next two decades. This announcement has generated debate about how plastic feedstocks will need to evolve as our economy decouples from fossil fuels and becomes more circular.

What is bio-based plastic?

Most plastics are currently produced from fossil fuels. The process begins with the extraction of oil, natural gas, or coal from the earth. The fossil fuels are then sent to a refinery where they are converted into petroleum products. The building blocks of plastic, known as monomers, are made from these petroleum products. The monomers are linked together to create a polymer in a process known as polymerization. The polymers are typically pelletized and sent to converters to turn them into plastic products.

Plastic can be made from anything that contains hydrocarbons – organic molecules consisting of hydrogen and carbon. Bio-based plastic contains monomers derived from organic biomass instead of fossil fuels. Examples of organic biomass used to make plastic monomers include sugar cane, corn, and bamboo.

Are bio-based plastics biodegradable?

Some are, but not necessarily! Conventional polymers, like PET, PP, and HDPE, can be made from bio-based sources. These polymers are identical to their fossil fuel-derived counterparts. They will not biodegrade easily, but they can be recycled if the article is designed for recycling, and the recycling infrastructure for the article is accessible in the region of use.

Biodegradation is a general term used to describe how an article is broken down by microorganisms within a given timeframe. Compostable plastics are a subset of biodegradable plastics. All compostable items are biodegradable, but not all biodegradable products are compostable, as illustrated in the diagram below. Composting requires specific conditions to break down materials, while biodegradable materials will break down naturally, but they tend to take longer than the composting process.

Source: Sustainable Packaging Coalition, Understanding the Role of Compostable Packaging

PLA is the most well-known and commonly used bio-based plastic in the market today. PLA is compostable in specific industrial composting conditions. PLA is commonly used today in plastic foodservice packaging, like drink cups and lids, and cutlery. Additional bio-based polymers entering the market for enhanced compostability and performance include PHA and PEF.

Is bio-based plastic circular?

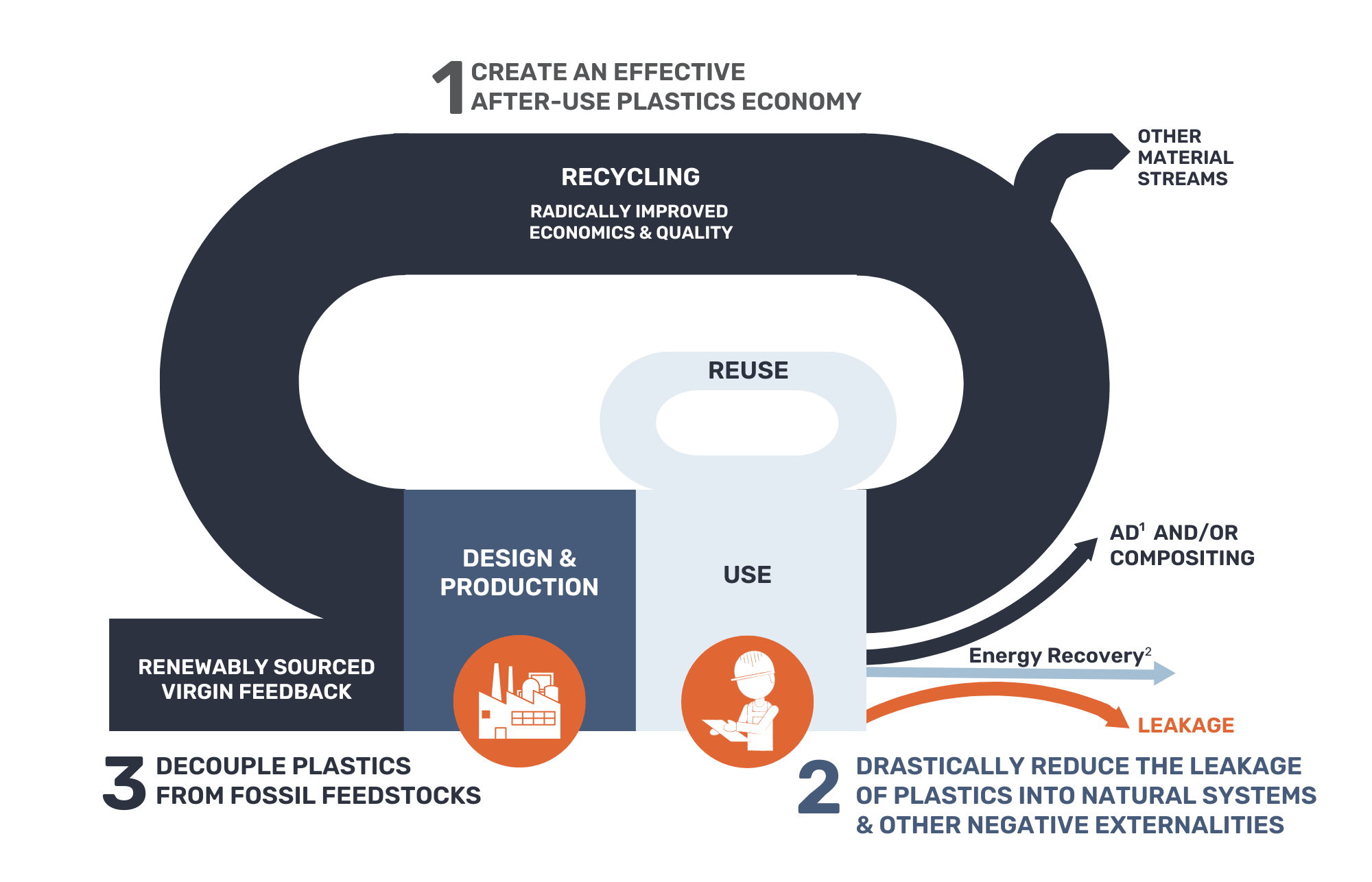

Creating plastic from renewable sources is a critical aspect of attaining circularity, as illustrated in the chart below courtesy of the Ellen MacArthur Foundation. Making plastic from bio-based materials provides a potential solution in this regard. It is important to note that bio-based materials tend to have higher water usage across their life cycle given the water required to grow them. The impact on greenhouse gas generation compared to fossil fuel sources is under debate. Growing and harvesting bio-based feedstocks requires agriculture equipment currently dependent on fossil fuel sources. However, these crops do absorb carbon dioxide from the atmosphere as they grow. Another consideration is land use, both in terms of its potential impact on the food supply chain and biodiversity. Sustainable agriculture practices will be critical to minimize these negative impacts as bio-based plastic production scales.

Source: Ellen MacArthur Foundation, The New Plastics Economy: Rethinking the Future of Plastics

The other critical aspect of circularity is end-of-life management. Ideally, materials are diverted from landfills so they can recirculate in our economy. Composting diverts materials from landfill but does not keep them available for recirculation. The energy and resources used to make compostable materials are depleted at the end of life. Compostable materials have the potential to contaminate established recycled material streams, like PET, if the consumer places compostable items in a recycling bin. Additionally, consumer access to industrial composting sites that accept packaging items is currently limited but growing.

Bio-based plastics that are recyclable at the end of life, like bio-based PET, do provide a clear pathway to circularity. However, improvements to recycling are necessary to make this vision a reality. Compostable materials can also contribute to a more circular system, especially for packaging items that are heavily contaminated by the product and thus not suitable for recycling.

Interested in learning more? The Sustainable Packaging Coalition’s guide to Understanding the Role of Compostable Packaging was extensively cited in the creation of this article.

Learn more about bio-based plastic in the following installment of Good Information.

Implementation of state-level extended producer responsibility (EPR) programs is starting to take shape. Four states have passed EPR legislation to date: Maine, Oregon, California, and Colorado. The EPR plan in Colorado took a major step forward recently with the selection of Circular Action Alliance (CAA) as the producer responsibility organization (PRO). The PRO is led by major brands such as Coca-Cola, Keurig Dr Pepper, General Mills, and Unilever, to name a few.

The PRO is responsible for implementing the extended producer responsibility plan in Colorado. This includes the establishment of minimum recycling rates in the state for packaging items covered by the law. The plan is due by February 1st, 2025. CAA is also under consideration in Oregon, California, and Maine for PRO responsibility in those states.

The following article from Waste Dive contains all the details: Colorado meets major EPR milestone.

PI’s sustainable packaging engineer, Sarah Webber, shared her insights on sustainable snack food packaging on the Packaging Perspectives podcast. The full podcast can be accessed here: Sustainable Snack Food Packaging.

Attending the Sustainable Packaging Coalition’s Advance event this September in Boston? Don’t miss our participation on a panel of experts from the Healthcare Plastics Recycling Counsel and Walgreens about Designing and Developing Sustainable Healthcare Packaging. Click here to register if you are a member of SPC: SPC Advance 2023.