The Challenge

Creating an Innovative, Cost-Effective 47” Catheter Delivery System Tray

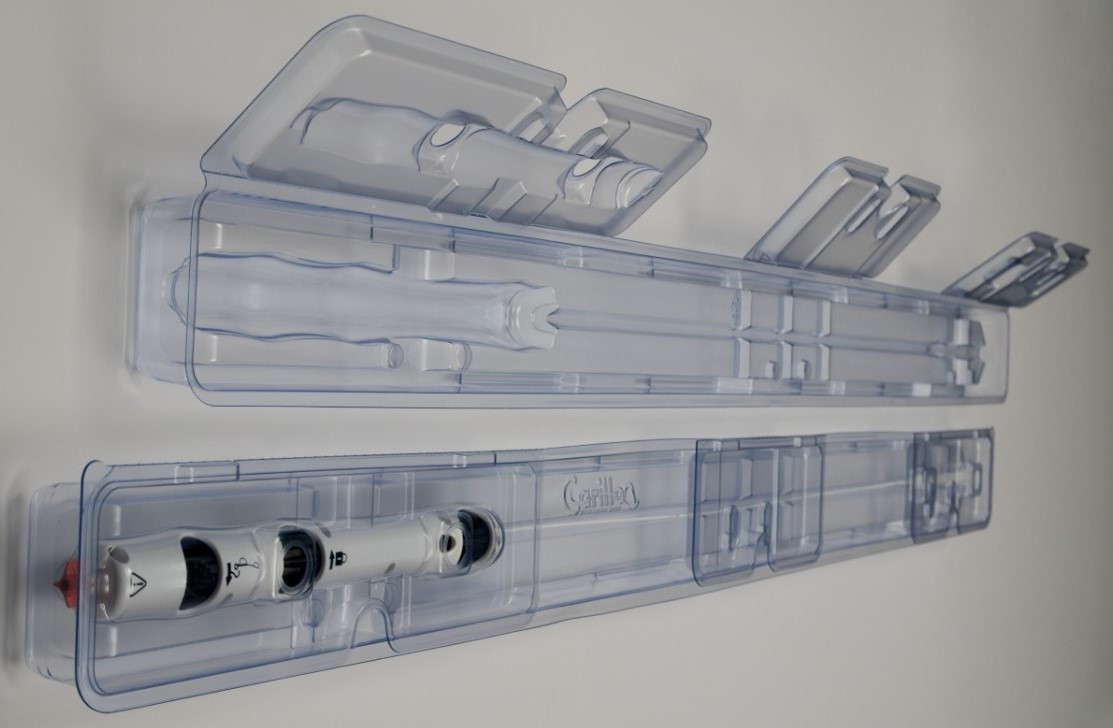

Cardiac Dimensions approached Plastic Ingenuity to create a tray pushing the boundaries of a standard medical device packaging solution. Developing a secure, sterile, cost-effective packaging solution for a 47” catheter delivery system posed several challenges—traditional thermoforming methods of a tray this length required sheet-fed processing, which was expensive and slow. Additionally, previous packaging designs relied on multiple die cuts and securing wires, which increased labor costs and overall complexity. Plastic Ingenuity was challenged with developing a highly complex tray that ensured product protection and sterility while addressing the high costs of producing this tray.

The Process

A thoughtful design update

Plastic Ingenuity proposed a breakthrough thermoformed package design that integrated roll-fed thermoforming and trim-in-place technology. The new design incorporated perforated hinges and snap features, eliminating the need for securing wires and reducing die cuts from twelve to four. These improvements streamlined assembly, enhanced product security, and simplified removal for end users. These enhancements reduced costs by two-thirds and increased production speed five-fold.

The package also introduced a tab feature, preventing sharp edges from puncturing the sterile pouch. Made from medical-grade PETG and formed in a clean room, it meets all biological and chemical safety standards.

The Solution

A new design delivered even faster

Plastic Ingenuity developed a cost-effective, efficient, and innovative packaging solution for the 47” catheter delivery system. The new roll-fed thermoforming method significantly reduced production time and costs while ensuring secure product protection. The improved snap features and perforated hinges eliminated the need for additional securing materials, streamlining the packaging process. The final package met all testing requirements, enhanced user convenience, and reinforced the company’s commitment to innovation and quality in medical packaging.

The Results

A Resounding Success

Less die cuts, from 12 to 4

Increased production efficiency by 5x

Reduced cost by 66%