Understanding the Language of Sustainability As the push for sustainable packaging grows,…

Welcome to Plastic Ingenuity’s blog series on packaging polymers! In this series, we will explore the different types of polymers used in packaging and their properties, applications, and environmental impact. We will also discuss the latest developments in sustainable packaging and how the industry is evolving to meet the growing demand for circular solutions. Join us as we dive into our first installment in a seven-part series with material #1: PET (Polyethylene Terephthalate).

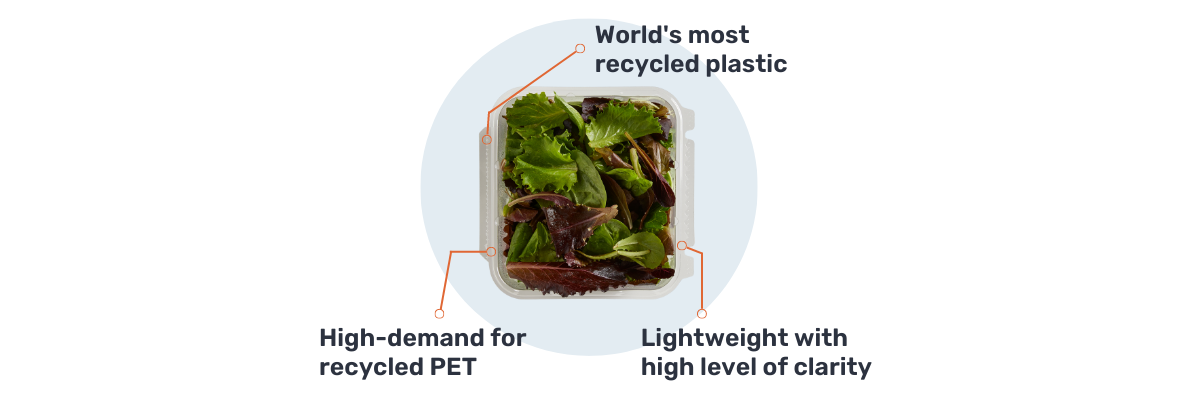

PET has many desirable properties for packaging applications. It has a high level of clarity for transparency to the product itself. PET packaging is lightweight yet possesses superior rigidity and strength. This is a primary reason it has a lower carbon footprint than glass and aluminum. PET can be efficiently molded in an almost endless number of shapes and sizes in a variety of conversion processes.

Here are some common packaging applications that use PET:

▪️ Bottled water and soft drinks: PET is widely used for manufacturing water and soft drink bottles due to its lightweight, shatterproof nature and ease of recycling.

▪️ Food packaging: PET is used for food packaging, such as trays, clamshells, and jars, because it is durable and has excellent barrier properties to prevent the entry of oxygen and moisture.

▪️ Personal care products: PET is used for packaging personal care products, such as shampoo, lotion, and cosmetics, because it is lightweight, shatterproof, and resistant to chemicals.

▪️ Pharmaceutical packaging: PET is also used for pharmaceutical packaging, such as pill bottles, because it is non-reactive and does not interact with the contents of the bottle.

PET (polyethylene terephthalate) is a highly recyclable material, which is one of the reasons it is commonly used for packaging. PET is the world’s most recycled plastic. In fact, about 1.6 billion lbs. of PET gets recycled in U.S. end markets every year. According to NAPCOR, the recycling rate for PET beverage containers is about 27%. The recycling rate for thermoforms is around 5-7%.

However, there is not enough recycled PET material from bottles to meet increasing demand. Recovering more thermoforms is a way to bridge the gap. Advancements in technology, like robotic sorting equipment and wash away labels, will enable more recovery.

Packaging creators can do their part by following recycling design guidelines. This is well within the control of packaging creators. Also, get involved with collaboratives, such as The Recycling Partnership, working toward improving system-wide challenges.

Recycling PET is an important way to reduce waste and conserve resources. It is also an effective way to reduce greenhouse gas emissions, as recycling PET requires less energy than producing new PET from raw materials. If we all do our part, the evolution to a circular economy will become a reality. For more information about sustainability in the plastics industry, visit www.plasticingenuity.com/sustainability