The Challenge

Enhancing Protection, Efficiency, and Sustainability

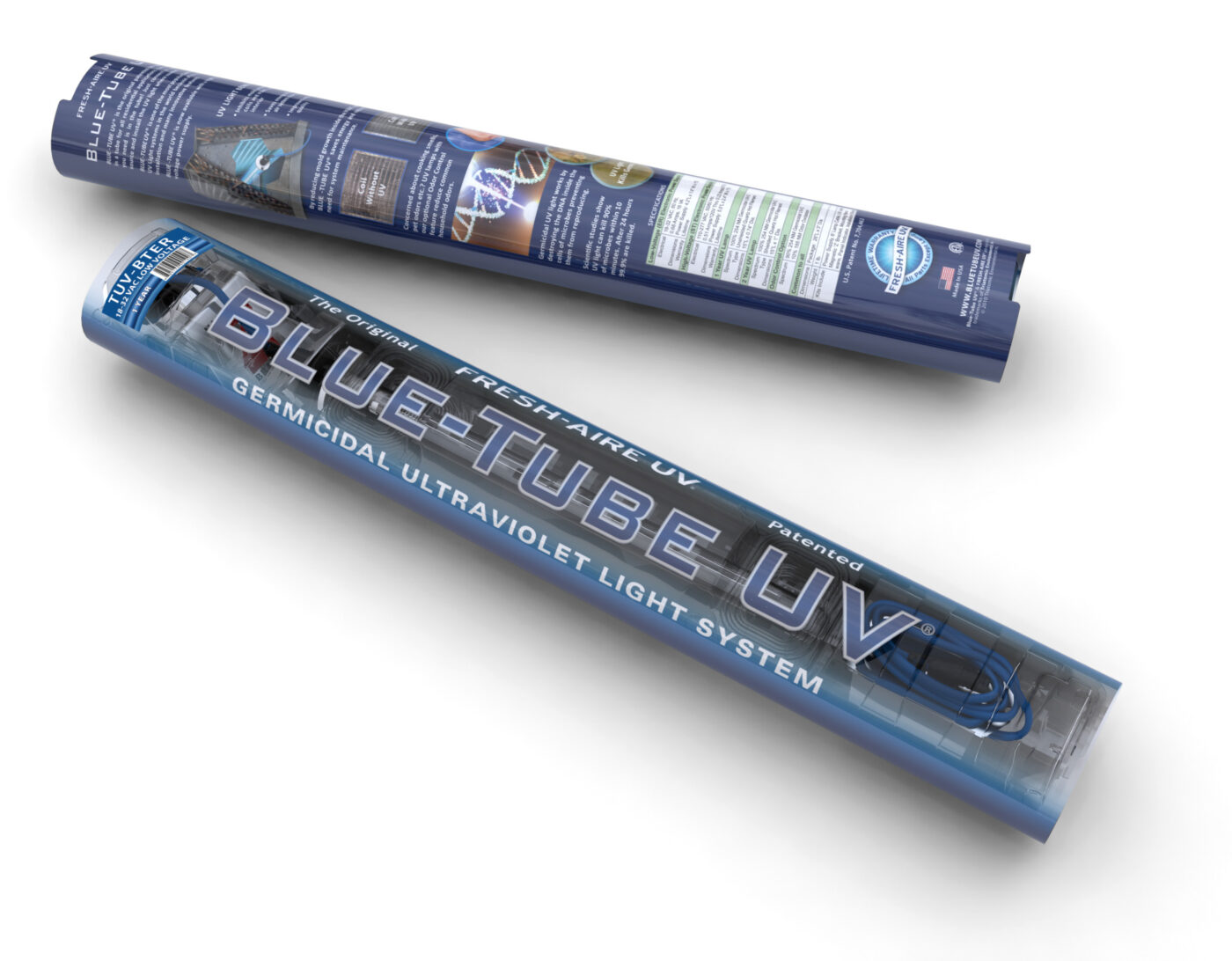

Triatomic, a manufacturer of germicidal UV lights, needed a packaging solution that could replace its existing design while addressing several critical concerns. The previous package required multiple parts depending on the product, relied on foam inserts for shock absorption, and involved stapling and taping, making assembly cumbersome and time-consuming. Additionally, the rigid plastic tube design took up significant storage space and was expensive to ship, as much of the volume consisted of empty air.

Triatomic sought a new solution to offer easy loading and product visibility, provide shock and cushion protection, and reduce assembly time, warehouse space, and shipping costs. The final goal was to enhance sustainability with recycled materials. Plastic Ingenuity considered all these factors and began addressing these concerns during the initial design process.

The Process

Innovative Snap-Together Design Reduces Costs and Enhances Efficiency

The package utilizes a single formed part that, when rotated 180 degrees, snaps together with another identical part to securely hold the UV lamp. This approach reduced mold costs and simplified production. A flexible “bellows” design was integrated to provide shock absorption and accommodate different diameter tubes without foam inserts. This eliminated the need for multiple custom components, reducing inventory complexity.

Snap caps were introduced to lock the outer sleeve onto the package, enhancing structural integrity and providing built-in tamper resistance. Unlike the previous rigid tubes, the new design features a collapsible outer sleeve and nested thermoformed trays, significantly improving space utilization and reducing inbound freight costs by approximately 70%.

The Solution

Optimized Packaging Delivers Efficiency, Cost Savings, and Sustainability

The final packaging iteration met all the manufacturers’ goals, delivering measurable improvements in efficiency, cost savings, and sustainability:

- Reduced Assembly Time: The new packaging cut assembly time by 50%, from 10 minutes per unit to five minutes.

- Lower Warehouse and Shipping Costs: The shift to a nested design reduced required storage space by 70%, freeing up warehouse capacity. Due to the optimized packaging structure, freight costs dropped from $0.55 per unit to $0.15 per unit.

- Enhanced User Experience: The package allows hanging and standing retail displays, improves product visibility, and doubles as a work tray for easy installation.

- Sustainability Gains: The switch from vinyl and foam inserts to recyclable PET trays and snap caps ensures an environmentally friendly solution.

The Results

A Resounding Success

Freight costs dropped from 55 cents to 15 cents per unit

Assembly time was reduced by 50%

Storage space was reduced by 70%