Welcome back to PI Circular – Healthcare Edition! In this issue, we reflect on our progress in 2024 and the challenges we’ve tackled to promote a circular economy for healthcare plastics. As we head into 2025, let’s celebrate the milestones we’ve reached and continue our journey toward meaningful change in the world of healthcare plastics.

1. HPRC Houston Pilot Project

The Healthcare Plastics Recycling Council (HPRC) has partnered with the Alliance to End Plastic Waste (AEPW) and Houston Methodist to launch a pilot program for recycling healthcare plastics in Houston, Texas. This initiative is key to establishing scalable models for recycling healthcare plastics. This project aims to divert single-use healthcare plastics from landfills and incineration while also creating a model for regional collaboration across the plastics value chain. The pilot will establish hospital collection systems, coordinate logistics and specialized sortation, and establish end-market pathways for material recovery.

The Plastic Ingenuity team is proud to support this effort as HPRC members, emphasizing the importance of collaboration in tackling challenges posed by healthcare packaging circularity. We are actively contributing resources to develop an economically viable model for other regions to adopt and coordinate sortation logistics for healthcare plastic waste.

Learn more about the pilot project here: Healthcare Plastics Recycling Pilot Planned for Houston

2. The Approval of the EU’s Packaging & Packaging Waste Regulation and Preparing for EPR

The European Union has officially approved the Packaging & Packaging Waste Regulation (PPWR), marking a significant step toward circularity for packaging. This regulation is part of the European Green Deal, which aims to reduce greenhouse gas emissions in the EU by at least 55% by 2030 and achieve net-zero emissions by 2050.

Key requirements of the regulation include designing packaging to be recyclable, setting mandatory recycled content targets for plastic packaging, enforcing PFAS restrictions, and implementing extended producer responsibility fees. These initiatives are intended to foster a more sustainable packaging framework and set a global standard for the packaging industry.

Product-sensitive items such as medical devices and pharmaceuticals are exempt from the design for recycling and post-consumer recycled (PCR) content requirements, although secondary packaging is not exempt. The product-sensitive clause will be reevaluated in 2035 to assess whether contact-sensitive packaging should be in the scope of recyclability requirements.

As we look toward 2025, many healthcare manufacturers are preparing for expected packaging requirements by transitioning to recyclable materials, developing plans to incorporate recycled content, and conducting recyclability testing to ensure compliance.

The latest version of PPWR can be accessed here: Packaging and Packaging Waste Regulation

3. Specialty Materials for Recyclability

The growing focus on recyclability in healthcare packaging is driven by impending regulatory requirements, such as the EU’s Packaging and Packaging Waste Regulation (PPWR) and corporate sustainability commitments. Recyclable materials like PET, HDPE, and polypropylene are emerging as preferred options for sterile barrier systems.

Plastic Ingenuity is leading the charge in these developments, assisting customers in adopting more sustainable materials while maintaining essential performance standards. These efforts underscore the growing momentum toward a circular economy in healthcare packaging.

If you’re interested in evaluating recyclable materials for your packaging system, reach out to our team to perform a Sustainable Packaging Assessment here: Connect with Our Sustainability Team

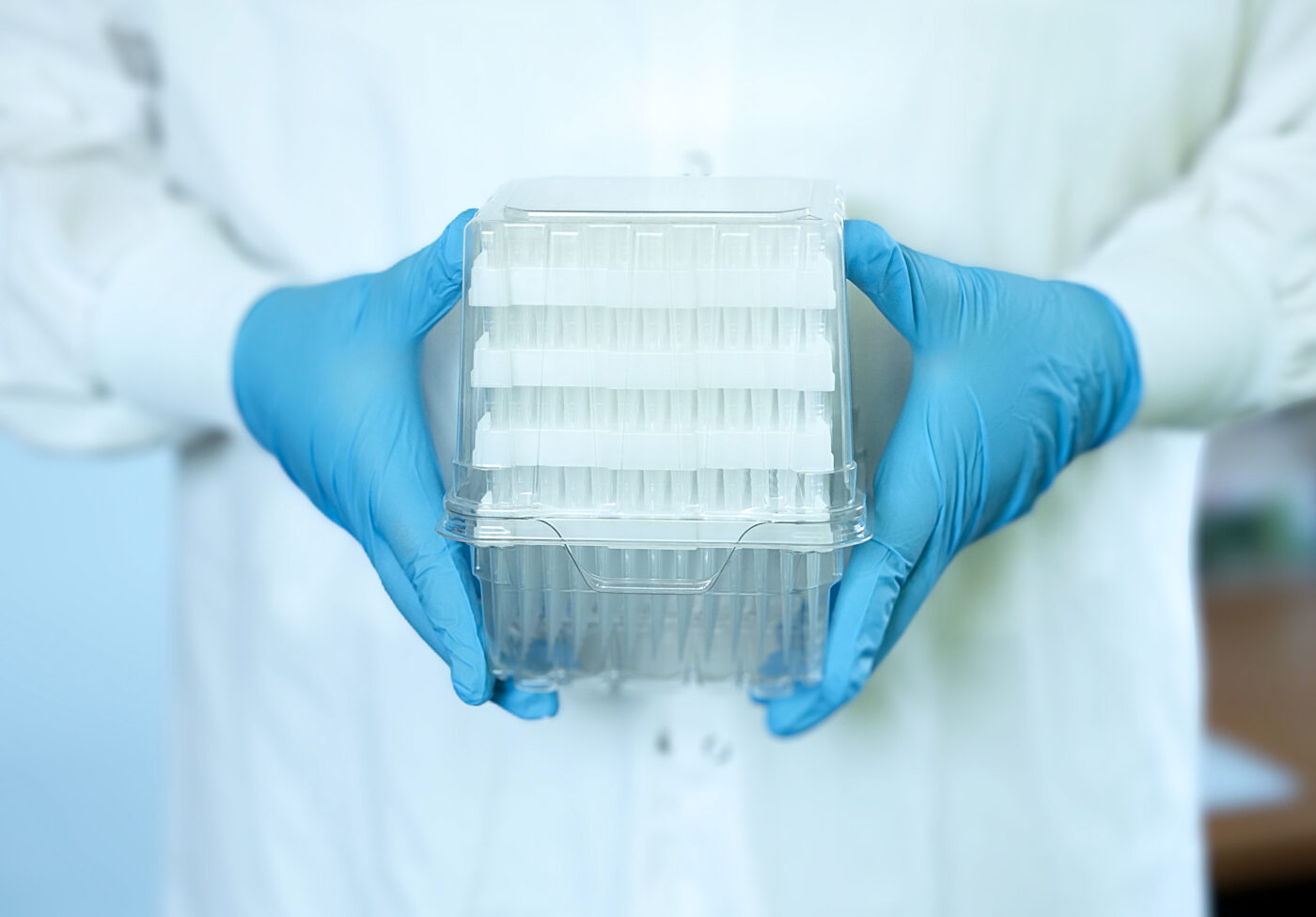

4. Plastic Ingenuity Wins IoPP AmeriStar Award for Beckman Coulter Innovation

One of our most significant highlights of 2024 was earning an IoPP AmeriStar Award for our healthcare packaging innovation with Beckman Coulter. This project showcased what Plastic Ingenuity stands for: innovation, sustainability, and high-performance packaging solutions.

The challenge was to design a custom thermoformed PET package for Beckman Coulter’s sensitive pipette tips, which are critical to their highly automated diagnostic machines. Over five years, we collaborated to refine the design, focusing on durability, material minimization, and recyclability. Through extensive testing, we developed a robust lid and tray system that protected the delicate components and incorporated user-friendly features like a unique contour trim for easier handling.

This award-winning solution achieved exceptional product protection while aligning with sustainability goals, highlighting the power of thoughtful design and collaboration.

Read more about the story here: Beckman Coulter’s Path to Sustainability Success (plasticingenuity.com)

5. Advanced Recycling is Here

Advanced recycling emerged as one of the top developments in healthcare packaging in 2024, driven by the trend to incorporate recycled content into sterile packaging without compromising performance or regulatory compliance. This approach relies on mass balance allocation, enabling advanced recycled materials to meet strict traceability requirements.

Several advanced recyclers achieved significant milestones this year. PureCycle successfully commercialized its polypropylene purification process, delivering its first shipment at the end of 2023 and processing over one million pounds of material in a week by September 2024. Similarly, Eastman commenced production at its depolymerization facility in Kingsport, TN, using methanolysis to break down polyesters into virgin-quality monomers.

These advancements enable healthcare packaging engineers to leverage circular materials, such as Eastman’s Renew, via ISCC PLUS certified mass balance systems, enhancing circularity while maintaining the performance standards critical for sterile applications.

- Our healthcare team will exhibit at MD&M West in Anaheim, California, from February 4th to 6th. To schedule a meeting with our team, contact us here: MD&M West | Plastic Ingenuity

- Join us for a webinar to discuss Designing for Sustainability in a Highly Regulated Environment. Register here.

- Our Sustainable Packaging Engineer, Sarah Webber, will be speaking at Smither’s Sustainability in Packaging in Chicago, Illinois from March 6th-8th.