Plastic Ingenuity has developed an Extended Producer Responsibility (EPR) video series as…

Welcome back to PI Circular! This edition will explore advanced recycling technologies and address common questions from brands.

Advanced recycling technologies are poised to transform plastic waste recycling. The technologies focus on recycling plastic waste that have traditionally been difficult to recycle economically, like polyester fibers and multilayer films. Advanced recycling techniques convert waste to polymer feedstocks or building blocks to create virgin-quality plastics. Advanced recycling creates circular pathways for waste that is not compatible with mechanical recycling.

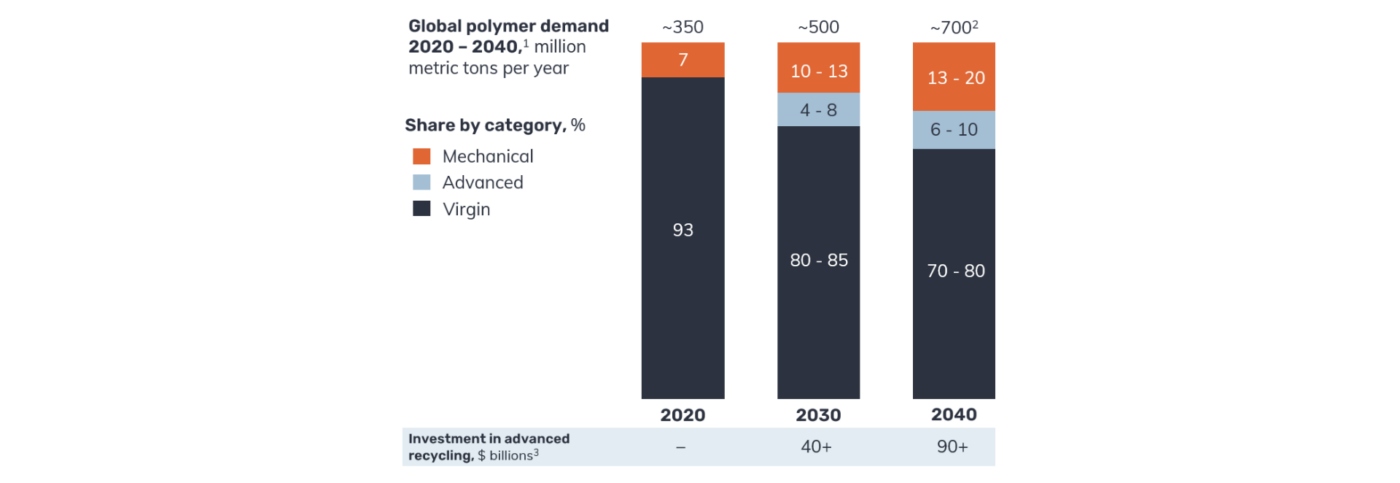

Advanced recycling’s ability to enhance plastic circularity has become a widely discussed topic. Significant investments have been made to increase the capacity of advanced recycling. A study from McKinsey estimates that the share of plastics made from advanced recycled feedstocks could grow to 20-40 million metric tons, or 4 to 8 percent of global demand by 2030. For context, 40 million metric tons is the equivalent of 110 Empire State Buildings in terms of weight. The following chart from McKinsey highlights the projected growth of advanced recycling over the coming decades:

What’s the Bottom Line for CPGs?

There are several questions brands frequently ask about advanced recycling. Our sustainable packaging engineer, Sarah Webber, will answer a sample of these questions below.

Q: Is advanced recycling the same as chemical recycling?

Sarah: Yes, that is a fair statement. Since advanced recycling is a group of novel recycling technologies, we have seen various naming conventions emerge. Advanced recycling and chemical recycling are the two most common. Regardless of what you call it, the technologies recycle plastic waste by converting them into the feedstocks or building blocks for new plastics.

Q: Is advanced recycling really better for the environment than using virgin materials?

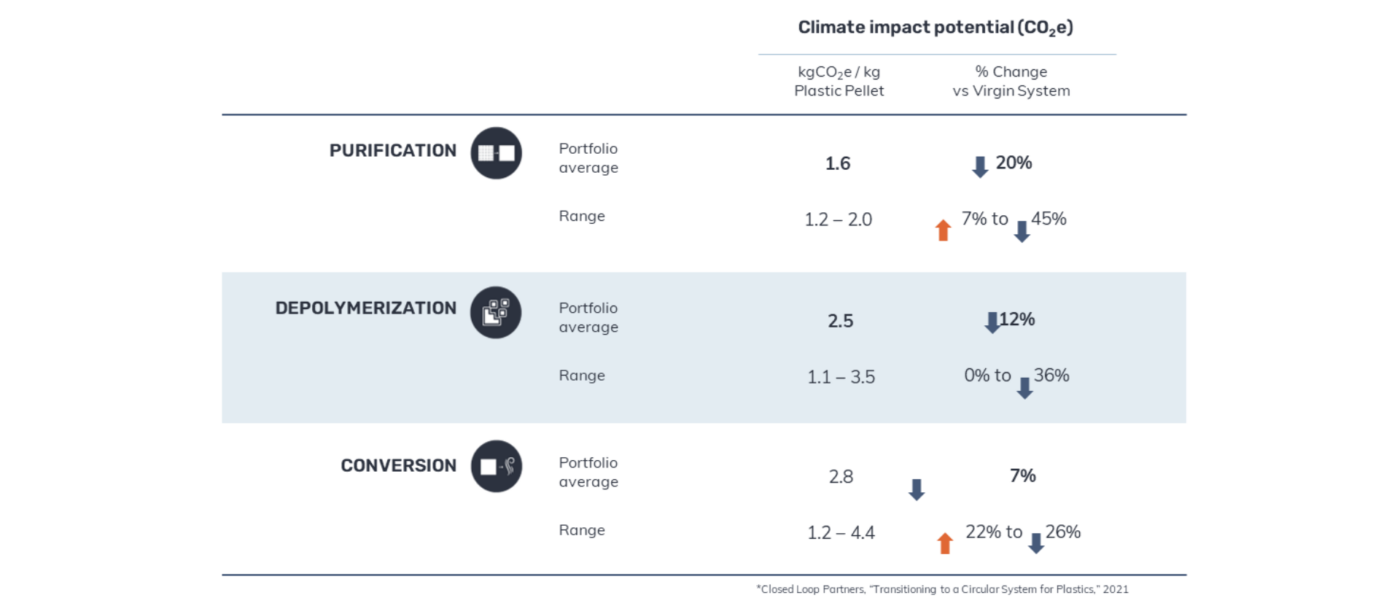

Sarah: Most life cycle assessments of these technologies have shown beneficial environmental outcomes associated with advanced recycling technology compared with using virgin plastics derived from fossil fuels. Closed Loop Partners examined this topic in their paper, Transitioning to a Circular System for Plastics. The chart below shows the greenhouse gas emission benefits of advanced recycling across various technologies deployed in the market:

Q: What are the byproducts of the process? Are they harmful?

Sarah: The byproducts depend on the specifics of the technology. For example, conversion uses heat and pressure to convert mixed plastic waste into hydrocarbons which can be used to make new plastics. The byproducts of this process include char and gas. The gas can be captured in a closed loop manner to fuel the reactor used to heat the waste. The char can be captured and sold to end markets, such as charcoal and landfill dressings. As with any operation, the facilities using these technologies at scale must abide by stringent local, state, and federal environmental protection laws including air emissions and pollution. Many states have passed laws specifying how these operations are classified to determine their level of regulation.

Q: Are any companies doing advanced recycling at commercial scale?

Sarah: Yes, there has been significant process in 2024 in the commercialization of advanced recycling. As with any new technology with this level of complexity, there have been challenges, but the overall arc of the technology remains intact. Examples of companies currently commercial include Eastman with their depolymerization process for PET, PureCycle for their purification process for PP, and Nexus with their conversion process for mixed plastics.

Q: Are the plastics made from advanced recycling identical to virgin polymers?

Sarah: This depends on the specifics of the technology. Plastics made from pyrolysis oil, the output of a conversion recycling process, will be identical molecularly to plastics made from fossil fuel since pyrolysis converts waste all the way back to the feedstock level. On the other end of the spectrum, purification uses a solvent to remove additives and impurities from plastic waste, but it does not break molecular bonds. The mechanical properties of the resulting recycled polymer will resemble that of a mechanically recycled polymer, but with a higher level of purity due to the purification process.

Q: How are brands approaching advanced recycling?

Sarah: Brands are interested in using circular materials derived from advanced recycling to meet their PCR targets. Many of these brands are members of the U.S. Plastics Pact. The pact recognized PCR from “chemical” recycling for as viable solutions as long as sufficient chain of custody schemes are in place (more on that below). Additionally, the Consumer Goods Forum Coalition of Action on Plastic Waste released a white paper detailing how “chemical” recycling can contribute to a circular economy.

Q: How are plastic producers scaling the technology?

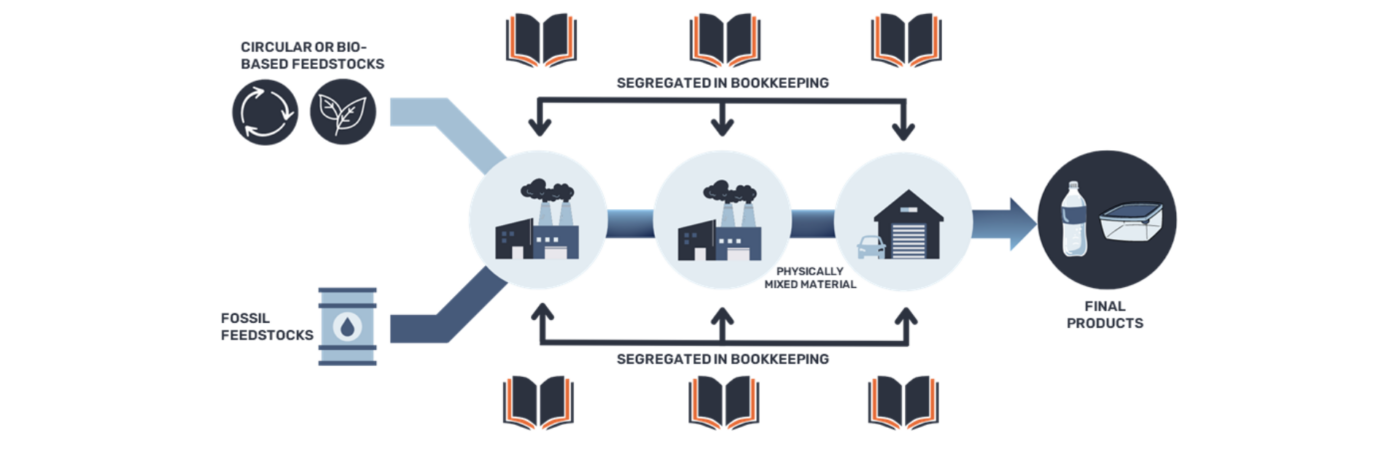

Sarah: Mass balance allocation is being leveraged to scale this technology. A mass balance chain of custody is designed to track the total amount of the circular materials through the production system and ensure an appropriate allocation of this content to the finished goods based on auditable bookkeeping. Mass balance allows resin producers to use the circular materials in their existing infrastructure, thus avoiding intensive capital investment. Mass balance is used commonly in other industries: renewable energy, cocoa, paper, etc.

Q: How can my brand adopt circular materials from advanced recycled into our packaging?

Sarah: From a performance standpoint, the advanced recycled materials are a drop-in replacement for virgin materials. The entire value chain must achieve 3rd party certification of their chain of custody systems to make a PCR claim. ISCC PLUS is the most common chain of custody system being adopted by the industry. Brands procuring packaging containing these materials must register as licensees and purchase the products from ISCC PLUS certified suppliers, like Plastic Ingenuity, to make PCR claims. The licensee registration process is much less complicated than the certification process.

Are you interested in learning more? Respond to this email to schedule a private “Lunch and Learn” webinar with our sustainability team.

Are you a packaging engineer, procurement professional, or a sustainability expert looking to learn more about the thermoforming process? PI has launched a free, in-depth online course covering everything from the polymers commonly used in thermoforming to the recycling process. This short yet comprehensive course is a great way for anyone to become well versed in thermoforming and rewards you with a certificate upon completion. Begin online today.

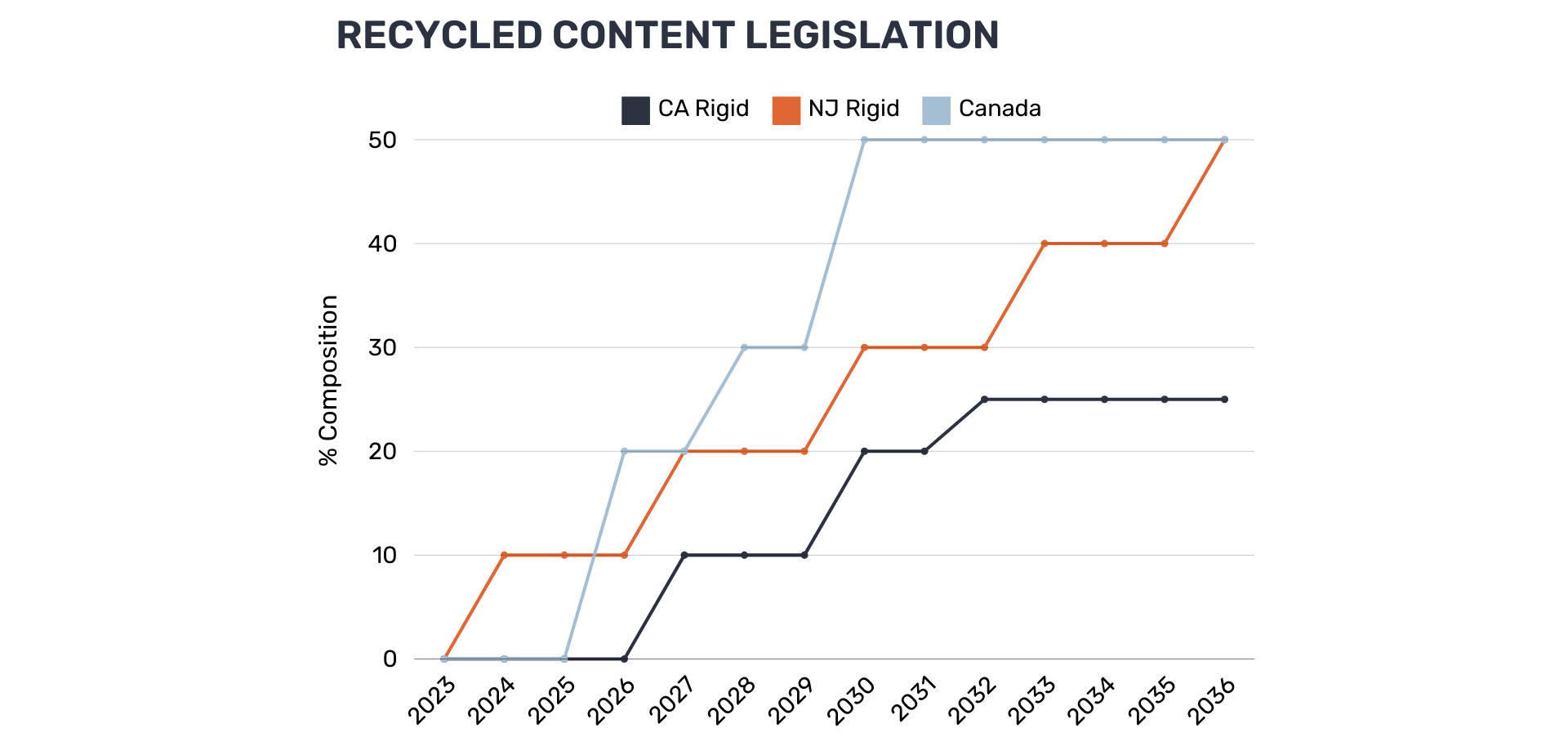

Minimum PCR content mandates are in effect in several states and will grow over the next decade. The intent of the mandates is to increase demand for recycled materials, thus providing an economic boost for recyclers. California, Washington, and New Jersey are states with PCR mandates in place today. Although mandates typically cover specific product types, like beverage containers and bags, other containers like thermoforms are in scope in several states. The following chart, courtesy of NAPCOR, highlights escalating PCR minimum mandates in PET thermoforms in California, New Jersey, and Canada.

Our corporate sustainability manager, Zach Muscato, recently shared his thoughts on how brands can transition to safe and sustainable packaging for snack packs: Reimagining Food Packaging – Packaging Technology Today

350 million metric tons: Global polymer demand in 2020

0 metric tons: Polymers derived from advanced recycled technology in 2020

20 – 40 million metric tons: Estimated share of global polymers derived from advanced recycling technologies in 2030

Our team is attending and presenting at many exceptional events this fall: